The use requirements and production of PE protective film

- 2022-03-04

- 660

- Wuxi Jianli Plastic Hardware Factory

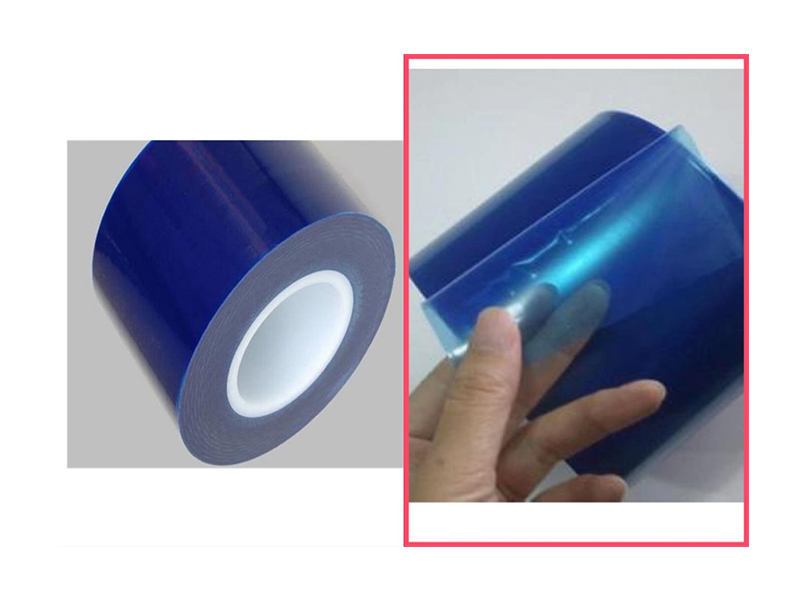

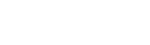

The advantage of PE protective film is that the protected product will not be polluted, corroded, scratched during production, processing, transportation, storage and use, and protect the original smooth and shiny surface, thereby improving product quality and market competitiveness.

Requirements for the use of PE protective film

1. Appropriate viscosity: easy to stick and easy to tear;

2. The peeling force is stable: the change over time is small, that is, the smaller the increase of the peeling force, the better;

3. Good weather resistance: under the condition of sunlight exposure, the service life can be as long as half a year to one year;

4. Long storage period: stored in the warehouse for more than one year, no change in quality;

5. No pollution and no corrosion: the adhesive is inert and will not chemically react with the surface of the adhered material;

6. Excellent mechanical properties: tensile strength, elastic modulus, elongation, etc. that meet user requirements.

The society of PE protective film is developing, human beings are progressing, people's requirements for the quality of life are constantly improving, and various new things are constantly appearing. It seems so ordinary, but it brings great convenience to our life.

In the past, there were problems in the packaging and transportation of some products. In the past, many of our products often had problems in the process of transportation. The common problem was wear and tear, which caused great economic losses. Because some items are basically useless once they are worn out.

In traditional packaging, the amount used in our food industry and medical industry is very large. The use of packaging in the past is very polluting to the environment. At the same time, the production process of pe protective film is constantly improving, and the scope of our use is also increasing.

- Prev:

- Next: