The production and application of protective film have developed rapidly

- 2022-03-04

- 242

- Wuxi Jianli Plastic Hardware Factory

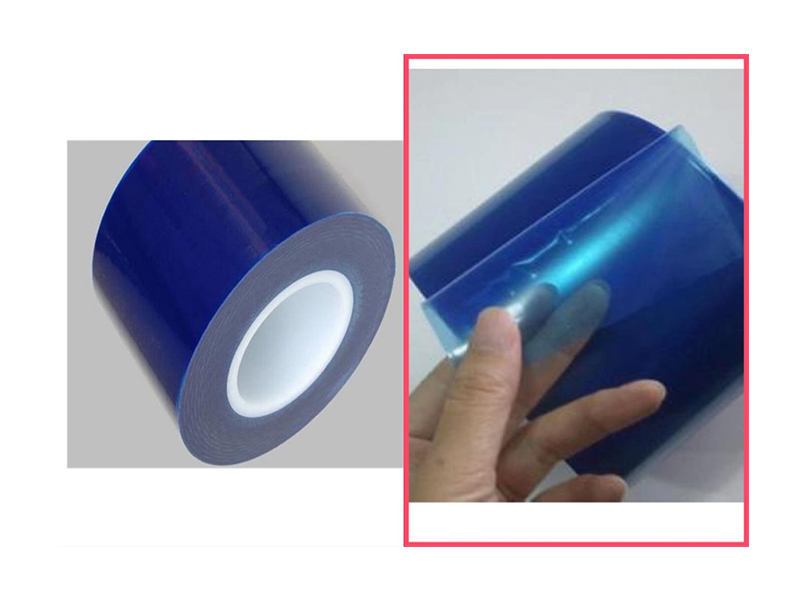

The PE protective film is a high molecular organic compound with a simple structure during operation. It mainly uses a special polyethylene (PE) plastic film as the base material. According to the different density, it is divided into high density polyethylene protective film, medium density polyethylene and low density polyethylene.

Among plastic packaging materials, the market demand for film materials has increased the most, accounting for about 46% of the total plastic packaging materials. Plastic packaging film mainly includes: heat shrinkable packaging film, wrapping packaging film, food aseptic packaging film, fruit and vegetable fresh-keeping film, liquid packaging film, etc. With the continuous improvement of the equipment level of my country's plastic film industry, some

Among plastic packaging materials, the market demand for film materials has increased the most, accounting for about 46% of the total plastic packaging materials. Plastic packaging film mainly includes: heat shrinkable packaging film, wrapping packaging film, food aseptic packaging film, fruit and vegetable fresh-keeping film, liquid packaging film, etc. With the continuous improvement of the equipment level of my country's plastic film industry, some have reached the advanced level of developed countries, and a number of new products have emerged. As a composite packaging substrate, biaxially oriented film has not only overcome the long-term import situation, but also It also exported about 300,000 tons, earning more than 3 billion US dollars in foreign exchange. The number of large-scale packaging film manufacturing enterprises in my country is developing rapidly.

The viscosity and other rheological properties of the adhesive are the most important properties that affect the coating behavior of the protective film. According to the dependence of the viscosity on the shear rate, the fluid can be divided into three types: Newtonian fluid, swelling body and pseudoplastic body. With the change of time, the fluid is divided into Newtonian fluid, thixotropic body and rheological body. The larger the rheological property of the adhesive deviates from the Newtonian fluid, the easier it is to have various quality problems in the coating operation, especially when the adhesive exhibits Due to the nature of the intumescent body, its viscosity will increase rapidly with the increase of the coating speed during the coating process.

In the past ten years, the production and application of protective film in China has developed rapidly and has become the largest producer in the world. With the development of science and technology and the improvement of living standards, higher requirements are put forward for the packaging of various industrial products. High-performance, functionalized flexible plastic packaging materials have become the focus of development and research, with high barrier properties, high transparency, Multifunctional fresh-keeping, aseptic flexible plastic packaging materials are increasingly valued by people, and show growing market demand.

At present, the production and application of domestic protective films are still in a high-speed and extensive growth stage. Due to the impact of the environmental protection wave, consumers have put forward higher and higher requirements for commodity packaging. Green protective film packaging is the need of the international environmental protection development trend, and it also represents the development trend of the packaging industry in various countries. It is one of the important contents to improve the market competitiveness of products and avoid new trade barriers. The greening of protective film has also become one of the important development trends.

- Prev:

- Next: